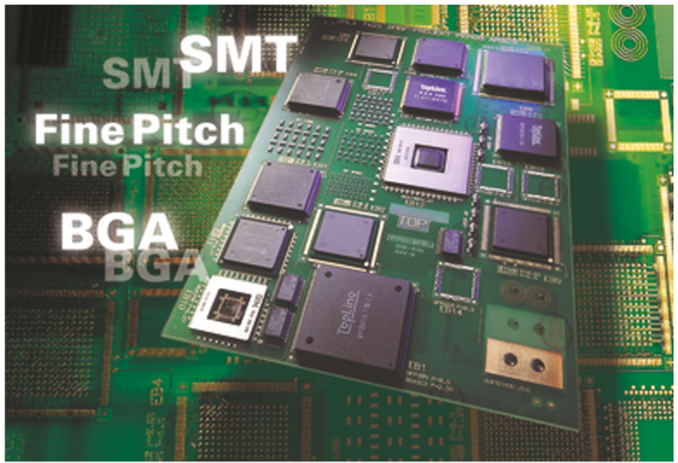

Nowadays, the electronic manufacturing industry is becoming more and more popular in modern society - where the demand for electronics and automation is increasing. Electronic components such as BGA (Ball Grid Array) require modern manufacturing methods. Industrial gases and auxiliary technology services are a factor contributing to the significant increase in production capacity of electronics manufacturing companies. Join Messer in Vietnam to discover how our industrial gas solutions and technology services will help you optimize your production.

- About Messer Group

- Comprehensive service

- Economic efficiency

- Analysis of the welding process

- Development projects

- Messer industrial gas in Vietnam – meet all your gas needs!

About Messer Group

Messer was founded in 1898 and is today the largest family-owned company in the world. We provide gas products and services in Europe, Asia and the Americas.

Our comprehensive product range covers the entire range of engineering gases; special gas and gas supply system. Our dedicated departments will support the application of these gases with customer orientation first.

Messer not only supplies gas, we also have a consulting team on circuit board assembly; provides services related to circuit board assembly. We partner with leading players in the electronics industry to develop new gas application technologies, covering the entire process chain from semiconductor manufacturing to circuit board assembly

Comprehensive service

The use of gases in the electronics industry (such as the use of nitrogen in welding) has long been standard practice. Messer offers a service plan that matches this application exactly.

Economic efficiency

Every application is precisely pre-researched economically. For example, choosing the right welding environment (residual oxygen content) and subsequently minimizing gas consumption.

Messer also advises you on the most suitable gas delivery system (such as on-site nitrogen production or liquid nitrogen supply).

If needed, we can perform an inspection at the customer's production site so that the process window can be optimized.

Analysis of the welding process

Although great care is taken, problems can still occur during the production process. Messer with its experienced experts will provide analysis services.

Cooperation with Fraunhofer Institute for Silicon Technology in Itzehoe (ISIT); We analyze the soldering and printed circuit assembly processes. Experts can also provide helpful advice and support in on-site process optimization.

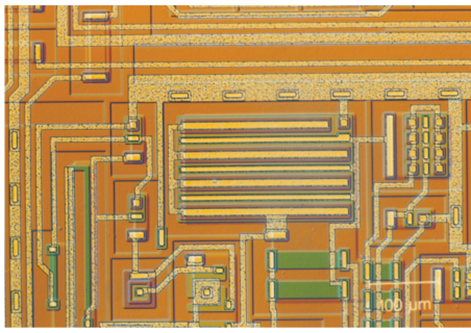

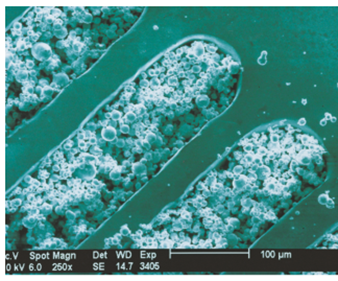

Very smooth cut of SMD (mask) die with copper vapor laser (CVL) CUZn36-foil, distance between pins < 100 µm

Together with our partners, we also analyze printed circuit boards and component surfaces with a variety of modern measurement techniques: for example, the metallic properties of finished products are examined by electron microscopy ; Substances on the surface (such as dirt, oxides) can be accurately determined with an atomic emission spectrometer (AES) and the surface mechanical properties are measured by atomic force microscope (AFM)

Development projects

In addition to providing a wide range of services, our development team is also closely involved in the transition of printed circuit production to lead-free technology. The actual implementation of our employees' technological know-how and the use of results from our basic research are at the forefront of these projects. The surface tension and bonding response of lead-free solders in an inert gas atmosphere with different residual oxygen contents have been of particular interest. This information is an important basis for PCB assemblers to decide on the selection of solder materials to be used.

An essential part of our philosophy is to develop solutions in collaboration with our customers. We provide our customers with bespoke solutions, tailored to their needs and based on our knowledge as well as that of our partners and independent institutes.

Messer industrial gas in Vietnam – meet all your gas needs!

As a leading gas producer in Vietnam, we have a modern and advanced system of gas separation plants throughout the country. Along with that is a system of large filling stations and high quality bottle factory. We are present in most key economic and industrial areas. Messer prides itself on having an extremely diverse product portfolio that can meet the maximum needs of its customers. Please see Messer gas product catalog here.

North of Vietnam: Mr. Nguyen Ngoc Diep

Tel: 0966852698

Email: diepnguyen@messer.com.vn

Central of Vietnam: Mr. Le Thien Tin

Tel: 0989244944

Email: letin@messer.com.vn

South of Vietnam: Mr. Nano Tran Hoang Nghia

Tel: 0909592599

Email: nanotran@messer.com.vn

Comments are closed.